PGRO Crop Update Number 4: 8th July 2025

PGRO Crop Update: CB2504

Number 4: 8th July 2025

Harvest and storage of pulses

Combining pea and field bean pre-harvest weed management

If the crop is infested with green weedy material, application of an approved glyphosate product will help with pre-harvest weed control. It must not be used on crops destined for seed.

Moisture content of combining pea seed should have fallen to 30%. At this stage, the seed is mature, and the crop yellow, lowest pods nearly brown and at the dry, "parchment" stage, those higher up being yellow. The seed within the pods should easily detach from their stalks and feel rubbery.

Apply when 90% of field bean pods are dry and black, most of the seed is dry and moisture content is below 30%. At this stage most of the leaves have senesced and fallen but the stems are still green.

Combining pea harvest

Care should be taken in harvesting peas, and if destined for the packet trade, chip shop or export, value is reduced if pea seed is "bleached" by the sun. Quality can be affected by wet weather at harvest causing staining in a lodged crop. If moisture content is low (~12%, or if they are over-dried), the crop may be unsuitable for human consumption, the percentage of 'non-soakers' increases, and the seed may split and crack. Peas for micronising for pet food must also have a good blue/green colour. Yield is lost due to shelling out and pod shatter if peas are left too long in the field.

Tips for combining:

- Combine in the opposite direction or at an angle to the direction of lodging.

- Lifting fingers are essential at least one every fourth position.

Adjustments may be necessary to lower the cutter bar close to the soil surface. - The reel is positioned slightly forward of the cutter bar and speed adjusted to lift the crop onto it.

- Combine settings - peas are easy to thresh so drum speed should be set to a low setting as per manufacturers recommendation.

- The concave should be opened up to reduce time the crop is in contact with the drum. Use high fan setting.

- The appropriate screen size for peas must be used.

- Quality is reduced by soil contamination. Do not combine when there is surface moisture on the haulm, or when the soil is wet, and make sure the combine is clean.

Peas can be combined when moisture content of the mature seed is 18% MC, and higher quality seed and human consumption is often achieved by early combining at 18-20% MC followed by careful drying. This avoids damage to the seed coat, and a higher percentage of non-soakers. Do not leave peas in the field until 12% MC. If peas are required for animal feed, they can be combined at moisture content lower than 18% and drying costs are reduced. At low moistures the seed may split, but split peas are still acceptable for animal feed. However, harvesting at such low moisture content may well significantly reduce the recoverable yield due to pod shatter and shelling out.

Field bean harvest

Beans are often perceived as able to withstand harvest delays long after other crops such as cereals have been harvested.

However, once beans are ready to harvest the quality will begin to deteriorate. If pods split and beans are exposed to light this will cause the seed coat to darken and increase the amount of crop loss during harvesting. When mature, cycles of wet and dry weather increase the chances of staining if they are not harvested. Quality is key to achieve any human consumption premium.

[image2/banner]

Drying and storage for combining peas and field beans

The quality standard for peas and beans is usually 14% moisture content (MC) with 2% impurities, or a combination of the two that should not exceed 16%. Drying can be more difficult with peas and beans than with cereals due to seed size, and while damaged produce is acceptable for compounding, mouldy produce is not.

The large size of bean seeds makes drying difficult as they have a low resistance to air flow. It takes time to move moisture from the inside to the outside hence slow, gentle drying with ambient air is best.

Peas and beans should not be over-dried and rapid drying at higher temperatures may affect texture and colour and seeds may split.

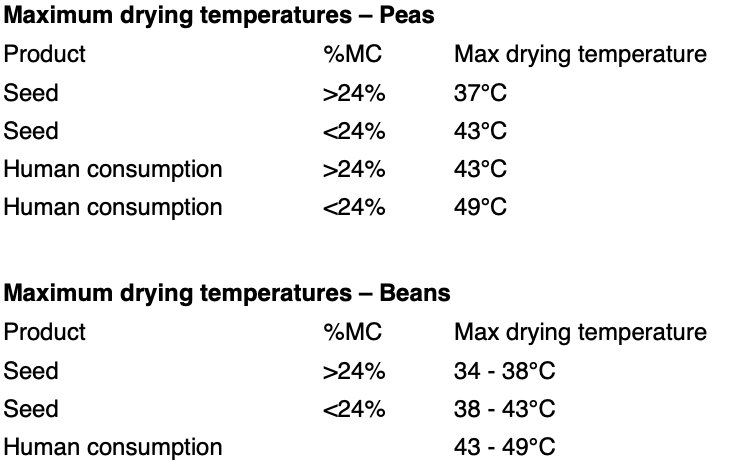

The tables below detail the maximum recommended drying temperatures:

Most types of dryer may be used for peas and beans, but those operating at low temperatures are safer. Mobile driers with small augers may increase cracking of pea seed and result in seed discoloration.

Floor-ventilated bins are easy and relatively safe to operate. When the initial moisture content is high, the transfer of the produce from bin to bin and the use of warmed air together with adequate ventilation may be necessary to avoid mould developing in the upper layers.

Radially-ventilated bins allow faster drying than floor-ventilated bins, but care must be taken not to overheat peas and beans.

On-floor drying using ambient or warmed air can be used and, provided there is sufficient volume of air and adequate ventilation, peas of relatively high moisture content can be dried using this method. Care must be taken not to load beans too deep if moisture content is high and if lateral ducts are spaced wider than 1 m.

Continuous flow driers designed to work on a short period/high temperature basis need more careful operation than other systems for peas. Use of continuous flow driers should be avoided for beans where quality is important since they may cause cracking.

Storage:

For safe storage, the maximum moisture content of peas depends upon the method and the length of time they are to be stored. Peas may be safely stored for up to 4 weeks at 17% MC, but if they are to be stored until the following spring, the moisture content should not be above 15%. If the peas are in bulk with forced ventilation or frequently moved, the moisture content can be 1% higher.

Storage in dark areas is recommended for beans destined for the human consumption market to delay the development of tannins which cause beans to discolour. Beans must be dried down to 14% MC for long-term storage in bulk - this is important since beans are often stored for some time before they are sold.

PGRO technical information

All PGRO Technical Updates have been revised to include the changes in pesticide availability for peas and beans. PGRO publications are available as free downloads from the PGRO web site www.pgro.org . User passwords are available on request through the web site.